- LEARN MORE

- +33 3 88 79 50 50

GENERAL REQUIREMENTS

NF EN 13688

OLD STANDARD EN 340

➤ Standard ISO 13688 is mandatory for PPE.

The standard does not protect against risks, and is always used in conjunction with one or more other standards.

Four types of requirement to be complied with :

FIT : Covers the body correctly

DESIGN : Based on functionality and comfort

MARKING : Labels in line with the standard

SIZE : Based on body measurements

STATIC ELECTRICITY RISK

NF EN 1149-5

PROTECTIVE CLOTHING WITH ELECTROSTATIC PROPERTIES

The standard specifies the electrostatic requirements and test methods for protective clothing that dissipates static electricity in order to avoid sparks that might cause a fire.

- The conductive clothing covered by standard EN 1149-5 forms part of a completely earthed system (conductive shoes, etc.).

- Standard EN 1149-5 is often combined with flame-retardance standards for explosion/fire risks.

➤ The fabric must contain a conductive fibre.

➤ Any antistatic PPE allows evolution in an ATEX environment.

➤ The ATEX legislation concerns only the environment and the equipment. ATEX PPE does not exist.

➤ ATEX areas are spaces where the presence of particles and/or flammable gases creates a risk of explosion.

Fuel (gas) or dust + reactant (oxygen) + spark = EXPLOSION

THERMAL RISK

EN ISO 11612

PROTECTIVE CLOTHING AGAINST HEAT AND FLAME

The standard specifies performance requirements for protective clothing made from flexible materials, which are designed to protect the wearer’s body, except the hands, from heat and/or flame.

For protection of the wearer’s head and feet, the only items of protective clothing falling within the scope of this standard are gaiters, hoods, and overboots.

➤ The standard protects against second- and third-degree burns, but not against first-degree burns.

➤ Raise awareness about the wearing of accessories (aprons, etc.).

➤ Home laundering with a fabric softener may impair the flame-retardant properties of the clothing.

➤ Advise the wearing of 100% cotton or flame-retardant undergarments.

➤ The standard does not apply to firefighting (EN 469).

WELDING RISK

EN ISO 11611

PROTECTIVE CLOTHING FOR USE IN WELDING AND ALLIED PROCESSES

The standard specifies the minimum basic safety requirements for protective clothing, including accessories that must be worn during welding operations and other technical processes with comparable risks.

➤ The standard protects the wearer, not the clothing.

➤ The clothing does not protect the hands, foot or head.

Class 1 LESS HAZARDOUS WELDING

Protection against low risks (low levels of spatter and radiant heat).

Class 2 MORE HAZARDOUS WELDING

Protection against higher risks (high levels of spatter and radiant heat).

➤ The type of welding determines the class of the PPE clothing.

➤ Grinding is not a welding process. There is no specific standard for this activity.

➤ Advise the wearing of 100% cotton or flame-retardant undergarments.

➤ Raise awareness about compliance with the changing rule so that the workwear is washed regularly, since traces of oil or stains may catch fire.

➤ The standard protects against second- and third-degree burns, but not against first-degree burns.

➤ Home laundering with a fabric softener may impair the flame-retardant properties of the clothing.

➤ The accessories supplement the protection and limit the appearance of holes.

Raise awareness about the wearing of accessories (gaiters, aprons, safety helmets, nape protection for the upright position).

➤ Professional maintenance maintains the flame-retardant properties of the clothing.

➤ The flame-retardant properties are reduced when the clothing is dirty. Wearing clean clothing ensures a proper level of performance.

ELECTRIC ARC RISK

IEC 61482

PROTECTIVE CLOTHING AGAINST THE THERMAL HAZARDS OF AN ELECTRIC ARC

The standard specifies requirements and test methods applicable to materials and garments for protective clothing for electrical workers against the thermal hazards of an electric arc.

IEC 61482-2 does not cover risks of electric shock, noise, UV radiation, metal fragments or toxic substances given off.

The performance of a garment is expressed by class (1 or 2) :

Class 1

Protection against 1 arc up to 4,000 amperes

Class 2

Protection against 1 arc up to 7,000 amperes

➤ Standard IEC 61482 protects only against the thermal effects of the arc.

➤ No metallic objects must be carried or worn: keys, jewellery, etc.

➤ Think about accessories (helmet, gloves, safety glasses, shoes).

➤ Flame-retardant or 100% cotton undergarments must be worn.

➤ Professional maintenance maintains the flame-retardant properties of the clothing.

➤ The flame-retardant properties are reduced when the clothing is dirty. Wearing clean clothing ensures a proper level of performance.

CHEMICAL RISK

NF EN 13034

PROTECTIVE CLOTHING AGAINST LIQUID CHEMICALS

The standard specifies the minimum requirements for limited-performance, limited-use and reusable chemical protective clothing.

- Type 6/PB6 clothing complying with standard EN 13034 is designed to provide protection in the event of potential exposure to light spraying, in cases of potential exposure to light sprays, liquid aerosols or low- pressure, low-volume splashes, which do not require a complete liquid permeation barrier.

- Six types of clothing are covered by the standard. Cawé offers only type 6 clothing.

➤ Type 6 corresponds to light spraying or misting of chemicals.

➤ Type 6 is not sufficient in cases where the concentration is greater than 50%.

➤ Raise awareness about the need to re-impregnate the clothing (impossible in home laundering).

➤ Embroidery is not permitted, since this creates holes in the clothing.

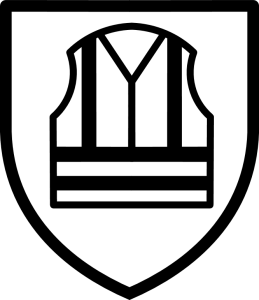

HIGH-VISIBILITY RISK

EN ISO 20471

HIGH-VISIBILITY CLOTHING

OLD STANDARD EN 471

The standard specifies requirements for clothing designed to increase the wearer’s visibility during the day, but also at night under illumination in car headlights.

The performance of the clothing is classified according to the minimum surface area of the fluorescent and retroreflective material.

FLUORESCENT FABRIC : Provides visibility during the day (orange, yellow, red).

RETROREFLECTIVE BANDS : Provide visibility at night and in dark environments.

➤ Class 1 + Class 1 ≠ Class 2

➤ Class 1 + Class 2 ≠ Class 3

➤ Class 2 + Class 2 = Class 3

➤ If the customer carries out road works, Class 3 is mandatory.

➤ For working in green spaces: give preference to fluorescent orange, since yellow attracts insects.

➤ Note on the size of bibs: maximum 290 cm² patch + bib (e.g. 10×9 patch and 20×10 bib).

KNEE PROTECTION

NF EN 14404

KNEE PROTECTORS

The standard defines knee protection requirements for all professional activities requiring work in the kneeling position.

➤ Work in the kneeling position involves the risk of chronic diseases such as bursitis and cartilage injuries caused by continuous pressure on the knees.

➤ Knee protection is therefore recommended for work performed in the kneeling position.

LEVEL 0 : For a knee pocket in the main fabric

LEVEL 1 : For a knee pocket in anti-abrasion fabric

➤ Think about Hygrovet knee pads.

➤ Level 0 certification : Flat surfaces

No penetration resistance is required.

➤ Level 1 certification : Flat surfaces

Penetration resistance of at least 100 N.

➤ Level 2 certification : Difficult conditions

Penetration resistance of at least 250 N.

COLD RISK

NF EN 342

PROTECTIVE CLOTHING AGAINST COLD TEMPERATURES BELOW -5° C

Category 2 PPE

The standard specifies the characteristics of protective clothing against the effects of humidity, wind and cold for temperatures below -5°C.

Three characteristics are specified :

Y: evaporative resistance

X: air permeability

Z: thermal resistance (insulation)

➤ Wearing of long-sleeved T-shirts, boot socks, hat and gloves.

➤ Wearing of long thermal underpants.

➤ Where sleeveless garments are required, only EN 14058 can apply.

➤ Avoid the wearing of jeans, as these are uncomfortable and permeable to cold.

COOL RISK

NF EN 14058

PROTECTIVE CLOTHING AGAINST COLD TEMPERATURES ABOVE -5° C

EN 14058 certified clothing is divided into three classes according to its thermal resistance.

➤ Wearing of long-sleeved T-shirts, boot socks, hat and gloves.

➤ Wearing of long thermal underpants.

➤ Where sleeveless garments are required, only EN 14058 can apply.

➤ Avoid the wearing of jeans, as these are uncomfortable and permeable to cold.

BAD WEATHER RISK

NF EN 343

PROTECTIVE CLOTHING AGAINST BAD WEATHER: RAIN, SNOW, FOG OR GROUND HUMIDITY

Standard EN 343 distinguishes two different types of performance :

X: Resistance to water penetration – 1 to 3

Resistance to water penetration measures watertightness, an essential factor for ensuring excellent protection. It corresponds to the pressure, expressed in kPa (thousands of Pascals), to which the material resists penetration by water.

Y: Evaporative resistance – 1 to 3

Evaporative resistance measures the fabric’s ability to evacuate the wearer’s water vapour, mainly perspiration. The test results are expressed in m2PaW. The higher this resistance, the more the clothing hinders the evacuation of the perspiration that accumulates on the body. The best index (3) is therefore obtained for low resistance values (≤20).

MEDIUM VISIBILITY RISK

NF EN 17353

MEDIUM VISIBILITY SAFETY APPAREL

The standard determines the characteristics of apparel intended to make the wearers visible in medium-risk situations, in daylight conditions or when illuminated by vehicle headlights or work lights in darkness.

The performance of the apparel is expressed as a class, depending on the type of materials used and how they are positioned on the apparel to provide the minimum area required for this standard.

FLUORESCENT MATERIAL

This ensures visibility in daylight.

RETROREFLECTIVE MATERIAL

This ensures visibility at night and in a dark environment.

COMBINED MATERIAL

This ensures visibility in daylight and at night.

➤ Class A : Equipment used in daylight, made from fluorescent material.

➤ Class B : Equipment used in darkness, based on retroreflective material.

Class B is divided into three sub-categories depending on how the retro-reflective material is arranged :

- Class B1 : free-hanging

- Class B2 : retroreflective on the limbs

- Class B3 : retroreflective on the torso and limbs

➤ Class AB : Equipment used in daylight, half-light and darkness, based on fluorescent and retroreflective material or material with combined characteristics.

Class AB is divided into two sub-categories depending on how the material is arranged on the apparel :

- Class AB2 : materials positioned on the limbs

- Class AB3 : materials positioned on the torso or on the torso and limbs